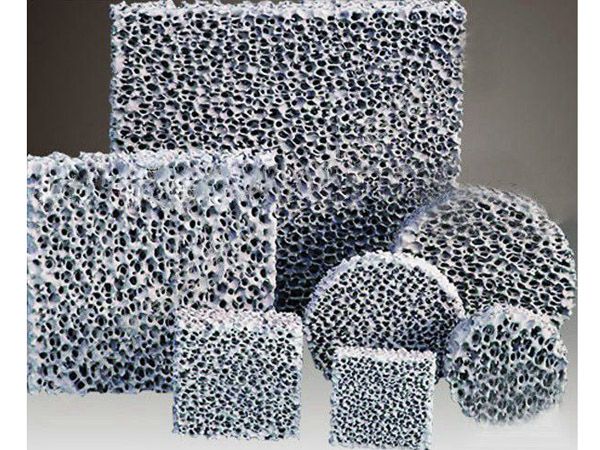

Ceramic filter is widely used in metallurgy, casting industry metal melt filtration, the use of mulolite (cordierite) ceramic material, high quality and high density straight hole mesh, so that the product has a high heat shock and high fever casting temperature characteristics, straight hole design to ensure the balance between flow and strength, effectively remove impurities and slag particles, etc. The mechanical properties, surface quality and product pass rate of castings are greatly improved.

Preparation characteristics

The new ceramic material has a natural chemisorption (affinity) ability to oxides, and absorbs impurities in the metal liquid (including particles smaller than the size of the hole) on the inner wall of the hole, improving the filtration effect. Advanced extrusion production process, so that the ceramic filter has a unique square and triangle design, it increases the contact area with the ceramic, improve the filter adsorption and capture the ability of fine impurities, than the non-extrusion filter filter filter effect is better, the metal liquid flow is smooth. Improved casting speed and continuity; Reduce castings scrap rate; Improve the mechanical properties of castings and prolong the service life. 3, foam ceramic filter is a special process, with foam porous structure of ceramic products, its chemical stability, high strength, high temperature resistance, good thermal shock resistance, large specific surface area and many other advantages, is widely used in metallurgy, casting, environmental protection and other fields.

TEL:0537-4591448

TEL:0537-4591448 Address:Hengmiao Industrial Park, Shimenshan Town, Qufu City, Jining, Shandong, China

Address:Hengmiao Industrial Park, Shimenshan Town, Qufu City, Jining, Shandong, China