Product introduction:

The product is processed by advanced production technology using edible grade starch, which has the characteristics of high adhesion, good fraction and complete environmental protection. This product is a special binder for casting sand, which can greatly improve the wet performance and dry strength of the casting model, improve the surface finish of the casting model, and is an indispensable bonding aid for the casting industry.

1. In addition to improving the hot and wet tensile strength of molding sand, the A-flow powder on the surface of the sand mold produces empty lines after being heated and burned, which can buffer the thermal expansion of silica sand. Thus, the anti-clamping ability of molding sand is greatly improved.

2. It can reduce the wear resistance between the molding sand and the shape, and improve the molding property of the molding sand. Reduce the mold waste rate due to poor drawing.

3, if the wet sand is placed for a period of time before the mold, the sand surface loses water and the surface strength decreases and is easy to wear, and it is easy to be washed out when pouring metal liquid. The problem is more serious when it is left for a long time or when the weather is dry. Adding a starch to mold sand can improve the ability of mold sand to resist air drying and reduce the sand washing defects of casting.

4. Starch can significantly reduce the sensitivity of molding sand to water, reduce the water content of molding sand and improve the firmness of molding sand. When mixing sand, if the water content of molding sand is low, it will appear rather dry and hard and brittle. Add a small amount of this product to molding sand, molding sand immediately becomes flexible, easy to shape and use. The effect is more obvious when using a starch with a higher degree of A.

5. The high temperature strength of molding sand is reduced, thus improving the knock out performance of molding sand.

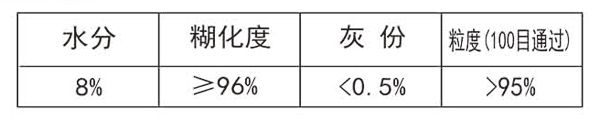

Product index:

Instructions for use:

Because cast iron is usually recycled old seconds, cast steel is usually new cotton sand, so. The amount of a powder added in molding sand is in cast iron. It's different in steel casting.

Cast iron generally does not exceed 0.5%(0.1-05%) Cast steel generally does not exceed 1% (0.5-1%)

TEL:0537-4591448

TEL:0537-4591448 Address:Hengmiao Industrial Park, Shimenshan Town, Qufu City, Jining, Shandong, China

Address:Hengmiao Industrial Park, Shimenshan Town, Qufu City, Jining, Shandong, China